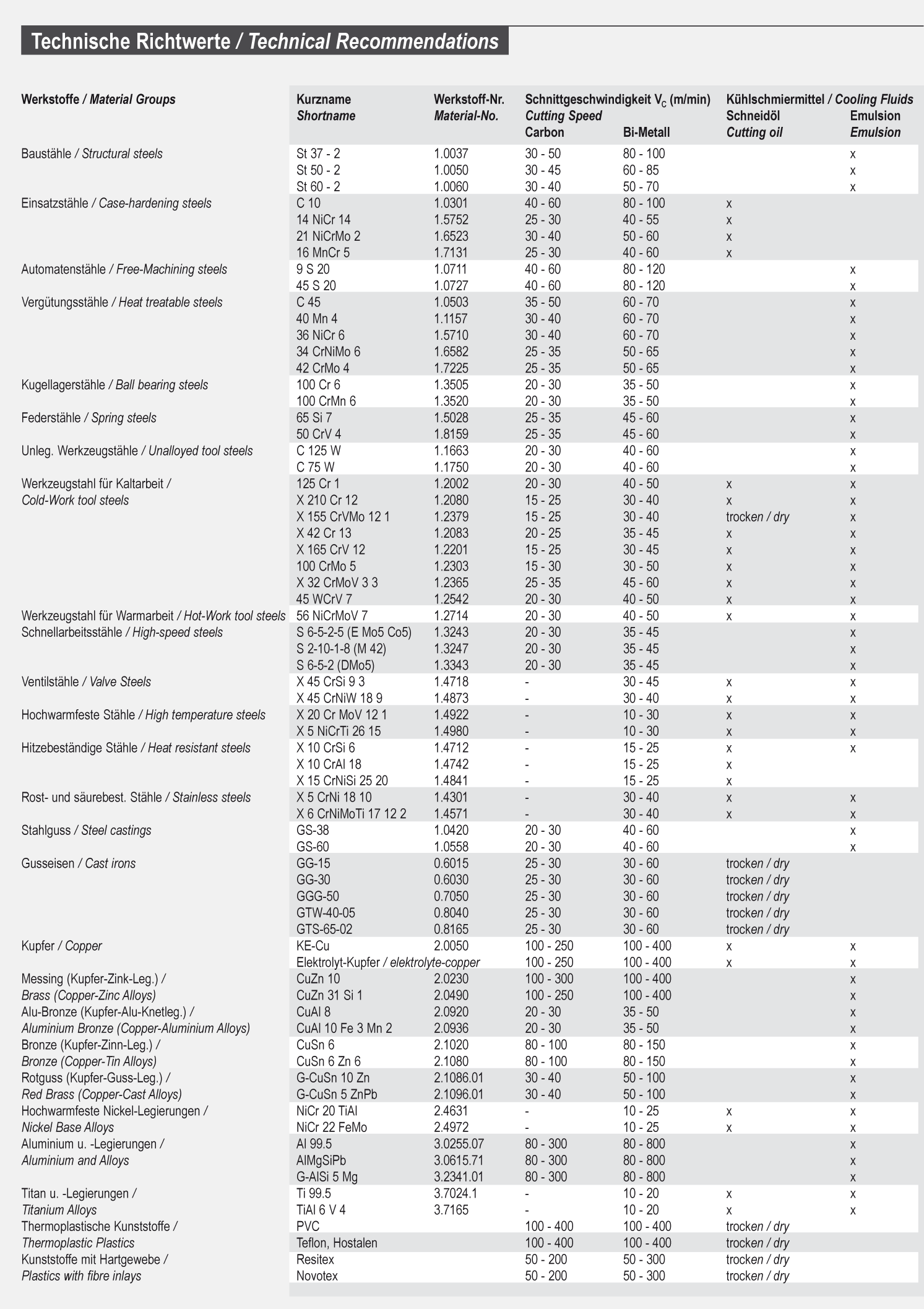

Technique band saws

Band saw blades Characteristics

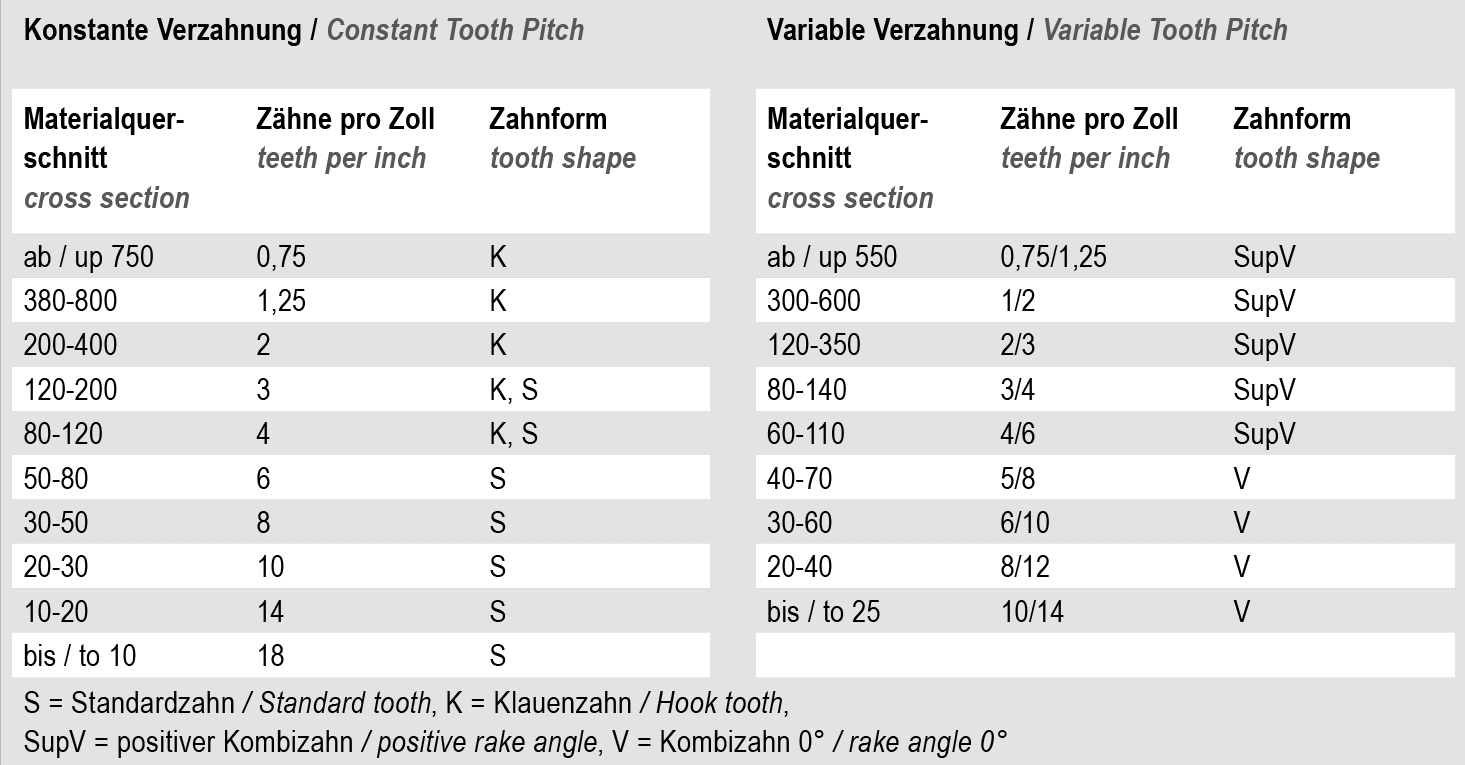

tooth forms

-

Button

Designed for:

• short chipping materials

• light wall thickness

Data:

• rake angle 0°

• 3 to 18 tpi

-

Button

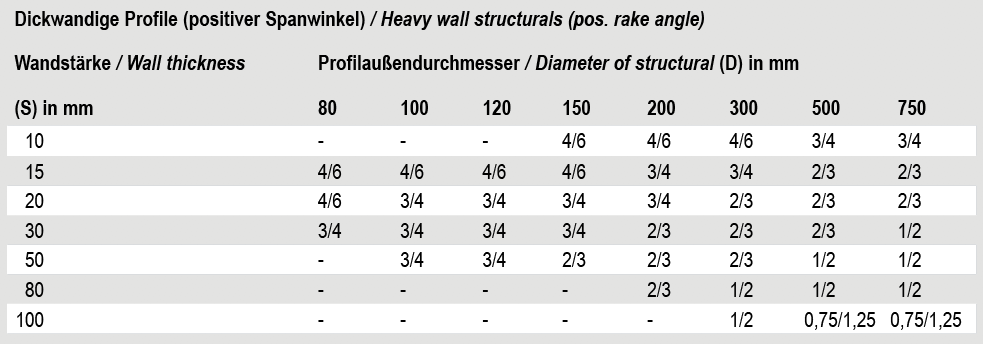

Designed for:

• long chipping materials

• large cross sections

Data:

• positive rake angle

• 0.75 to 6 tpi

-

Button

Designed for:

• low vibration cutting

• structuals

Data:

• rake angle 0°

• variable tooth pitch of 3/4 to 10/14 tpi

-

Button

Designed for:

• low vibration cutting

• solid materials

Data:

• positive rake angle

• variable tooth pitch of 0.55/0.75 to 4/6 tpi

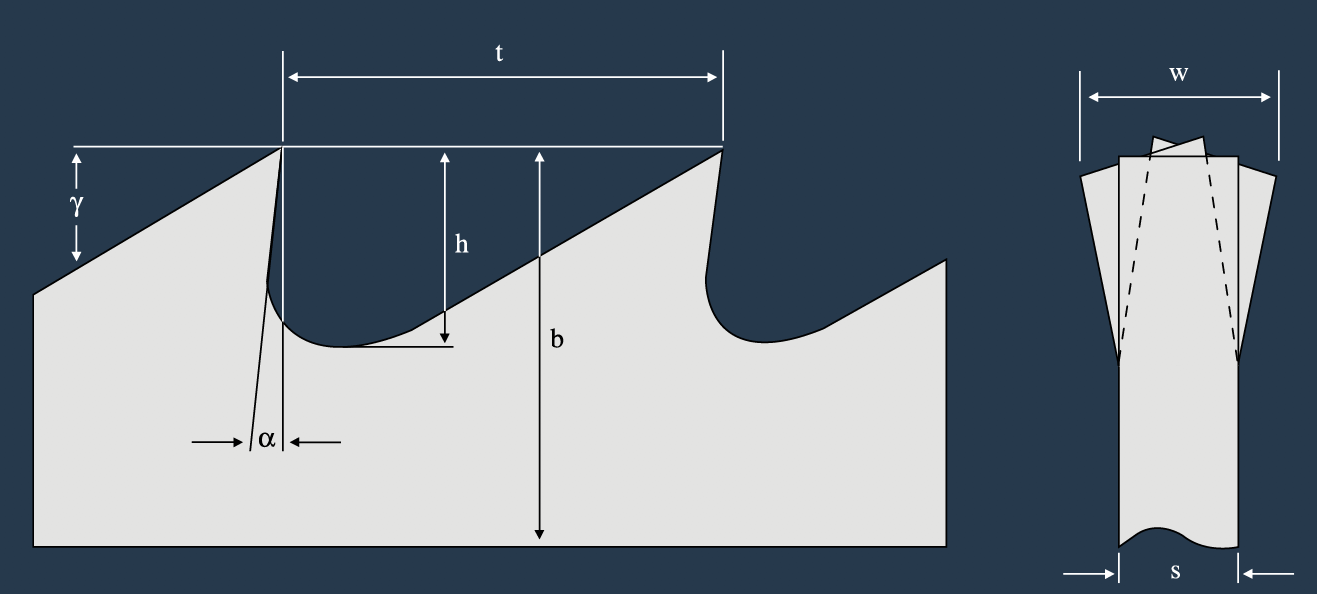

geometry

-

Button

b. bandwidth

S. thickness

h. tooth depth

t. tooth pitch

a. rake angle

y. clearance angle

w. setting width

tooth set

band width

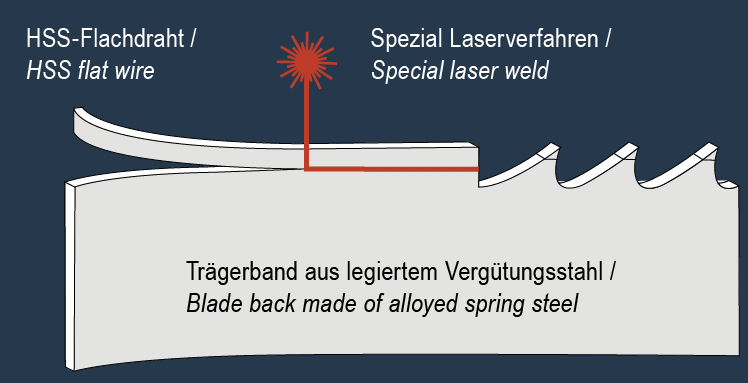

bi-metal

-

Button

Flexible:

The blade back of our Bi-Metal band saw blade consists of a special alloyed spring steel. Highly flexible at a hardness of about 50 HRC. The ideal basis for long fatique life and excellent cutting performance.

Hard and wear resistant:

Tooth tips made of hardened HSS Steel in M42 or MPM quality.

Perfectly joint:

Both materials are undetachably welded together.

All advantages:

The high quality Bi-Metal band combines the flexibility of the spring steel backing with enormeous wear resistance of highspeed steel. Each tooth tip is of hardened HSS-steel, extremely durable for best performance.

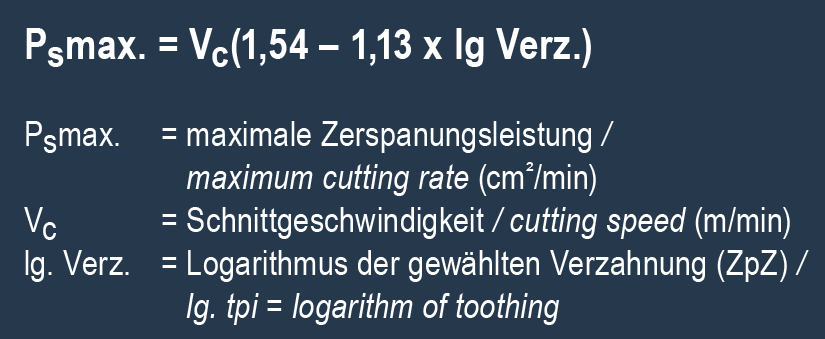

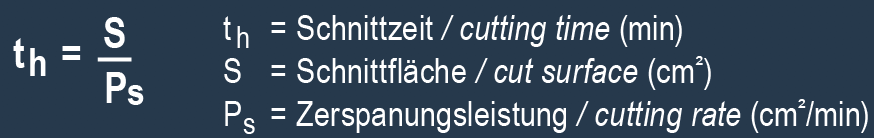

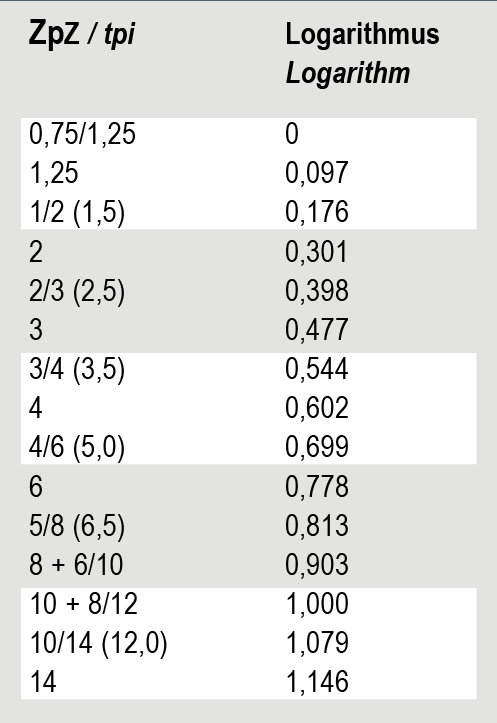

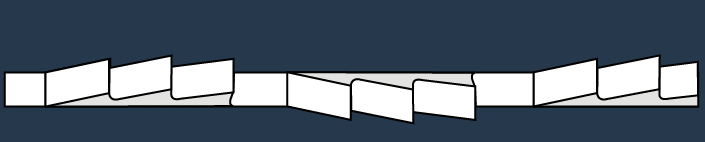

tooth pitch

Produce best chip load with the right feed-rate.